Livart Marine

Livart Marine, a member of Livart Group, was founded in 2007. After more than 10 years development, Livart Marine is a well known international famous company in marina business, it provides premium floating solutions to worldwide clients from design, engineering, fabrication, installation and maintenance.

MORELivart Standard Livart prides itself as the one-stop customer-focused centre; involving from proposal stage to full engineering design, manufacturing, installation,testing & commissioning and final completion stages.

Visual Identify

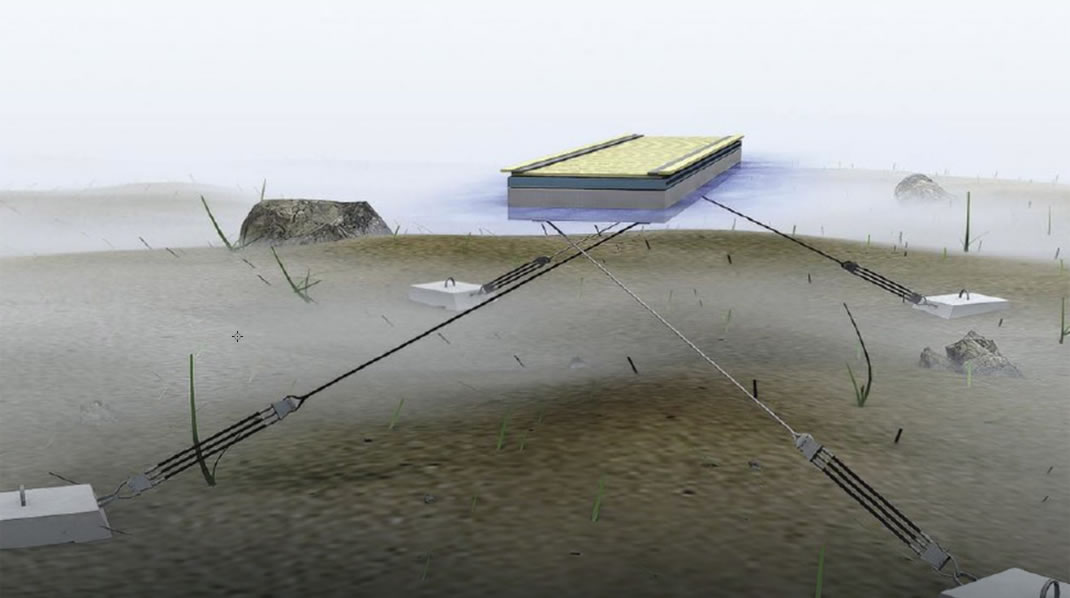

Based on the international standard, in according to marina site's environmental conditions, Livart Marine has a full set of calculation of the wave, wind, currency and boat impact

Marina Design

Based on the international standard, in according to marina site's environmental conditions, Livart Marine has a full set of calculation of the wave, wind, currency and boat impact…

Materials Test

Materials Test

Fabrication Inspection

Fabrication Inspection

Installation Procedure

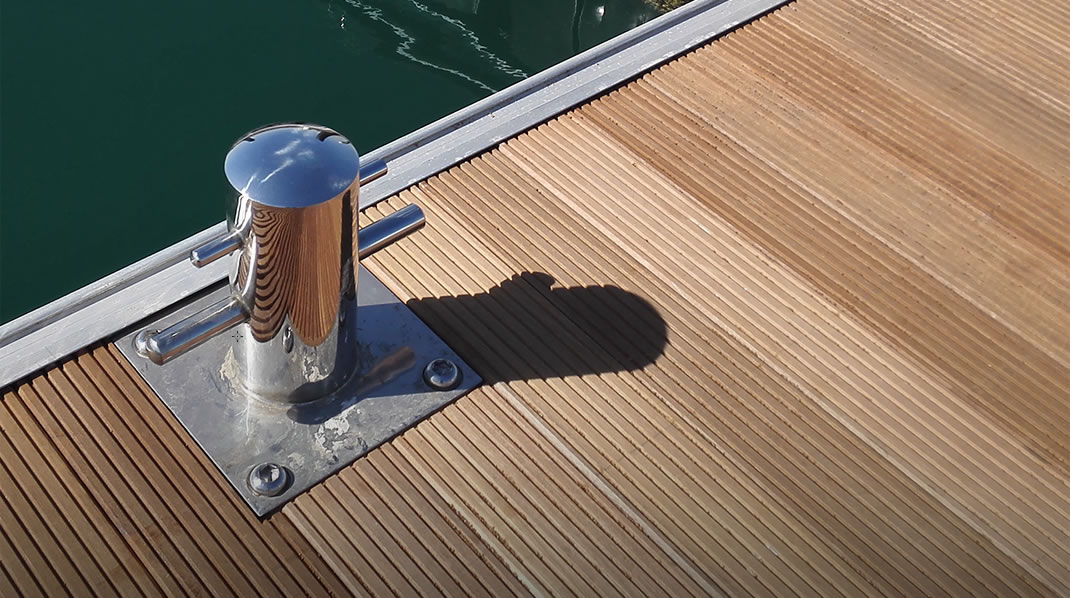

Operation & Maintenance

The pontoon can be made more beautiful and safer by carrying out regular repair and maintenance, which can also extend its service life.

World

Reference

Europen /

Malta

Kalkara Boat Yard Club-Phase I, Aluminium Floating Pontoon, was designed and constructed by Livart Marine, total 40 berths, completed on November 11, 2011.

View more +Mediterranean /

Holland

Holland Marina, Aluminium Floating Pontoon, was designed and constructed by Livart Marine, total 30 Berths, completed on October 5, 2008.

View more +Africa /

Uganda

Lake Victoria Marina Club, Aluminium Floating Pontoon, was designed and constructed by Livart Marine, total 35 berths, completed on May 1, 2013.

View more +Mid-East /

Dubai Nash Marina

Dubai Nash Marina, Aluminium Floating Pontoon, was designed and constructed by Livart Marine, total 34 berths, completed on April 10, 2014.

View more +South East Asia /

Korea

Namhae Sailing School at Namhae Moolgun, Korea, supplied by THE WINAVE; Aluminium Floating Pontoon, was designed and constructed by Livart Marine, total 50 berths, completed on December 1, 2011.

View more +China Mainland /

Tianjin Rainbow Marina

Tianjin Rainbow Marina, Concrete Floating Pontoon, was designed and constructed by Livart Marine, total 82 berths.

View more +Oceania /

Dominica Marinas

Dominica Marinas, Aluminium Floating Pontoon, was designed and constructed by Livart Marine, with a total construction area of 120 m², completed on December 25, 2014.

View more +East Asia

Mainland

Contact Us

-

Head

Office -

Factory

Location -

World

Distributor